Our content is funded in part by commercial partnerships, at no extra cost to you and without impact to our editorial impartiality. Click to Learn More

Machine Vision lets you automatically inspect production or manufacturing outputs, giving you high-quality instant reports and automating pass and fail checks. By using sophisticated machine vision cameras and simple cloud-based software, you can put your business’s production overview at your fingertips.

For example, machine vision can be used to instantly inspect a busy production line. The cameras can be set up to scan barcodes on items; count the number of products in a batch; or measure sizing and check for discrepancies in an instant.

The best machine vision systems are powered by user-friendly software, that can give you advanced analytics to help you understand your production line and improve your business efficiency.

The most important question, of course, is how much a machine vision system could cost for your business. The easiest way to find out is by using our simple quotes tool – you just need to put in a few key details about the scale and needs of your business to get started in moments.

In this Guide:

- Machine Vision Cameras – learn more about the imaging equipment that powers machine vision

- Machine Vision Software – simple interfaces and deep analytics to understand your production line

- Machine Vision Pricing – understand the costs of a Machine Vision system

Machine Vision Cameras

Machine vision cameras are the eyes and ears of any machine vision system. These sensitive, super-smart cameras run instant checks on supply lines, scanning codes, capturing product dimensions, and identifying potential issues in fractions of a second.

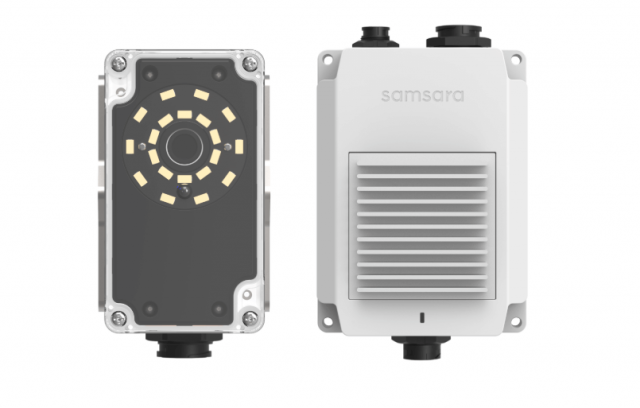

For example, the Samsara VS2 machine vision camera system (pictured) is perfectly engineered for a factory environment. It can operate in temperatures up to 50ºC, and capture your supply output at hummingbird speed thanks to sensitive autofocus and exposure times as rapid as 1/10,000 of a second.

How Does a Machine Vision System Work?

With a machine vision system, you set up cameras to check your production line or other key section of your work site. The camera sensors then automatically detect and record each product that passes it – often, in fractions of a second. Their recorded images are processed using machine vision software.

You can set your criteria for a “pass” – ie a product at correct quality – and the software can then detect failures or other outliers. Deep reporting is then possible, and thanks to the images captured by the machine vision cameras, you can always refer back to examples of any items deemed to have failed inspection checks.

The real benefit of a machine vision system is how effortlessly it can automate an otherwise time-consuming and laborious checking process. There’s less room for human error, and a fast-moving production environment can be monitored at vast scale by modern cameras and powerful software.

Machine Vision Software

Production supply environments are complex, with a huge number of moving parts and a busy daily output. To understand trends and spot anomalies, you need software that can drill down into detail, while being simple to use and clear in its presentation.

The best machine vision software can display all the data you need, clearly and effectively. The machine vision cameras capture what comes through your production line, and the cloud-based software creates an instant record.

The machine vision software can show you pass and fail rates, batch or item numbers, and image records of the items coming through your supply line. Any time there’s an outlier or a spike in failure rates, you can dig into the software reporting, and advanced machine learning can help you spot trends and monitor for inefficiencies.

Machine Vision Companies

Machine vision may sound niche, but it’s quickly becoming a hotly-contested industry. As such, there are a couple of big name brands in the space, including Cognex, Teledyne, and even global tech giant Samsung via its engineering arm.

One of the most innovative is Samsara, already well known for its commercial fleet tracking solutions. Samsara’s approach to machine vision has been to modernize and simplify its deployment, cutting down on complex setup periods and helping clients to get up and running as quickly as possible. Its VS2 machine vision system combines “integrated hardware and cloud-based software to simplify previously complex and costly setup processes”.

The software itself can be accessed from any device with a web browser, making it easy and effective for multiple staff at your business to get deep-data reporting of all production outputs.

Which Businesses Can Benefit from Machine Vision?

If you’re running a production process, then it’s likely that machine vision could help your business to run more effectively.

Take the food-packing industry, for example. With a machine vision system in place, you can automate everything from checking the dimensions of the plastic packaging that a supermarket burger comes in, to quality-checking the size and shape of each patty, to ensuring the printed labels are correctly attached and without smudging or poor legibility.

The market for machine vision is huge, and growing. It was valued at $9.1 billion in 2018, and is projected to reach $14.6 billion by 2024.

Machine Vision Pricing

A modern machine vision system is an investment for your company, and one that can significantly improve efficiencies and reduce overheads in the long term. Naturally, there are initial costs to consider when getting set up with a machine vision system in the first place, as well as ongoing costs for the cloud storage system that manages all your business’s data.

The hardware costs for machine vision cameras can run to thousands of dollars. On top of this, you’ll need to consider software costs for the back-end data processing, plus setup costs and considerations over the number of licences you need. The overall pricing will vary depending on the scale of your operation, and the number of product records that will be created in the machine vision system.

Every business is unique, and there’s no one-size fits all solution when it comes to costing up a machine vision system. That’s why we recommend you compare some quotes to help you get started – a machine vision company will be able to tailor a price to the scale and requirements of your business. You can get started with this process by using our simple quotes tool, which will help you get quotes for a machine vision system for your business in a few easy steps.

If you click on, sign up to a service through, or make a purchase through the links on our site, or use our quotes tool to receive custom pricing for your business needs, we may earn a referral fee from the supplier(s) of the technology you’re interested in. This helps Tech.co to provide free information and reviews, and carries no additional cost to you. Most importantly, it doesn’t affect our editorial impartiality. Ratings and rankings on Tech.co cannot be bought. Our reviews are based on objective research analysis. Rare exceptions to this will be marked clearly as a ‘sponsored’ table column, or explained by a full advertising disclosure on the page, in place of this one. Click to return to top of page